FSU researcher joins $50M Department of Energy consortium to create powerful sodium-ion batteries for electric vehicles

Of the nearly 300 million cars on the road in the U.S., about 10 percent are electric, a market that is growing due to an increasing variety of vehicle options and drivers’ desires to lower fuel costs and reduce emissions. While many electric vehicles on the market are powered by lithium-ion batteries, the cost and environmental impact of lithium extraction is driving innovation in battery design.

A Florida State University chemist is part of a nationwide research team confronting these issues through a major U.S. Department of Energy consortium created to help reduce reliance on critical elements — chemical elements that are in high demand for various industries and are in limited supply.

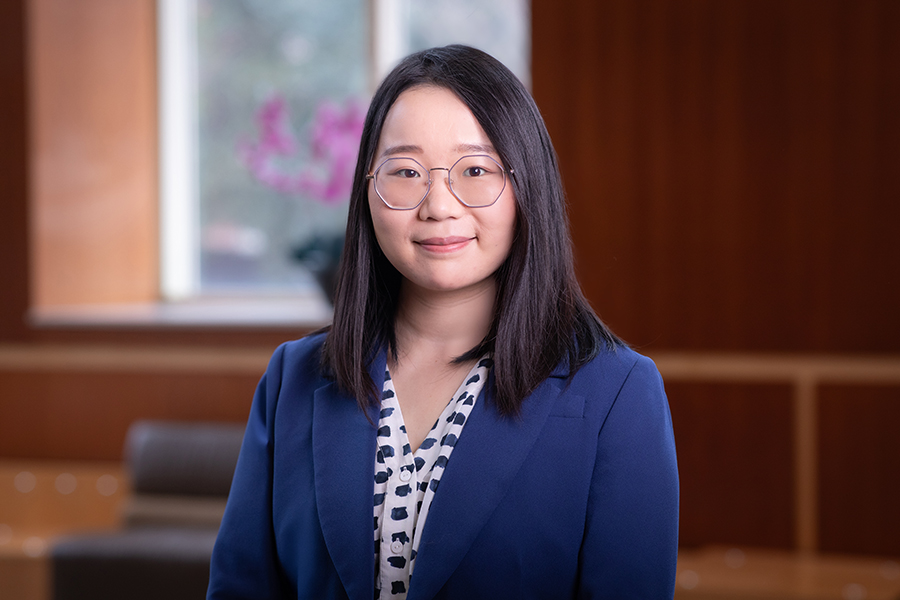

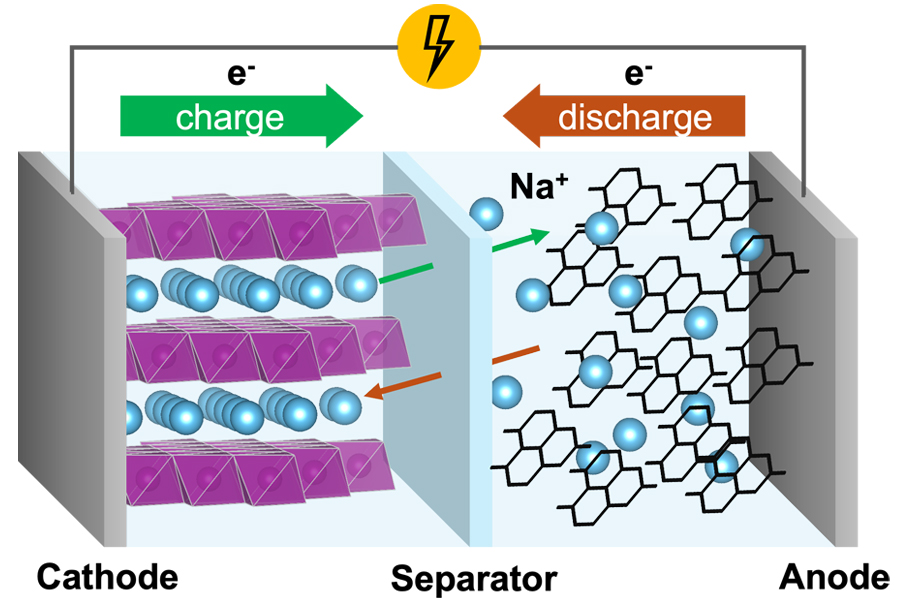

Assistant Professor of chemistry and biochemistry Yan Zeng has been funded as part of the DOE’s $50 million Low-cost Earth-abundant Na-ion Storage Consortium, or LENS Consortium, which aims to discover, develop and demonstrate a new class of sodium-ion batteries for use in electric vehicles. Zeng will use the more than $300,000 allotted to FSU over several years to fund the development of more efficient cathodes, a critical component of every battery that determines how much energy can be stored in the battery and how much energy it supplies to a car. A cathode is the positive part of the battery, in which transition metals gain electrons and reduction reactions occur when the battery is in use.

“Sodium and lithium are very similar, and sodium batteries have been commercialized in other countries like China,” Zeng said. “However, there are no sodium-ion battery-powered electric vehicles in America yet — this is the country’s first big push toward environmentally friendly, affordable electric vehicles. There’s also a big supply chain issue with lithium, and alleviating this problem is critical to increase the economy’s supply chain resiliency.”

This project is funded by the DOE Vehicle Technologies Office and brings together researchers from six national laboratories and eight universities to create novel materials and methods to combine and create powerful sodium-ion batteries. In addition to its role in creating cathodes, Zeng’s group is unique in its use of tools like artificial intelligence and robotic-driven platforms in material synthesis.

“We’ll use two different approaches to synthesize the target materials needed to create cathodes,” Zeng said. “The first is called solid-state reaction where we mix different element ingredients, like different metal oxides, carbonates and other salts, and ‘bake’ them at a high temperature in chamber or tube furnaces. Our second approach is solution-based in which we crystallize a material from a solution, and the resulting materials are analyzed to determine what works together and what doesn’t. We have a robot arm doing repetitive work for the lab to increase efficiency, and we use AI algorithms to suggest what sorts of parameters could improve the outcome.”

Because sodium is slightly heavier than lithium, sodium-ion batteries provide lower energy than lithium-ion batteries of the same weight and size. Zeng’s group will overcome this disparity by creating new element and structure combinations to pack as much sodium in the cathode structure as possible, allowing for these new sodium-ion batteries to be even more powerful than lithium-ion. Once the materials with these new elemental and structural combinations are created and analyzed, Zeng and her group will travel to national laboratories to collaborate on special designs enhancing the cathode alongside other scientists.

“Yan is a pioneer in the rational design of solid-state materials,” said Wei Yang, chair of the Department of Chemistry and Biochemistry. “Because of its chemical complexity, designing environmentally friendly and cost-effective sodium-ion batteries is challenging, and gaining new insights through repetitive work is costly and time consuming. Integrating AI-informed learning and a robotic-driven platform, like Yan has done, provides a promising solution to long-standing challenges, has attracted tremendous national and international attention, and speaks to the department’s strength in our data-driven molecular science development.”

Additional members of the consortium hail from the University of California San Diego, the University of Houston, the University of Illinois Chicago, the University of Maryland, the University of Rhode Island, the University of Wisconsin-Madison and Virginia Tech. Participating national laboratories include Argonne, Brookhaven, Lawrence Livermore, Pacific Northwest, the SLAC National Accelerator Laboratory — formerly the Stanford Linear Accelerator Center — and Sandia National Laboratories.

“It means so much to me that I received this funding in my first year at FSU,” Zeng said. “I’m very thankful to the department and university for helping me set up my lab and build a great team so quickly, allowing me to deliver my best work to the consortium as fast as possible.”

To learn more about Zeng’s work and research conducted in the FSU Department of Chemistry and Biochemistry, visit chem.fsu.edu.