Chemistry researchers explore use of new materials to create more efficient solar cells

that can use infrared light.

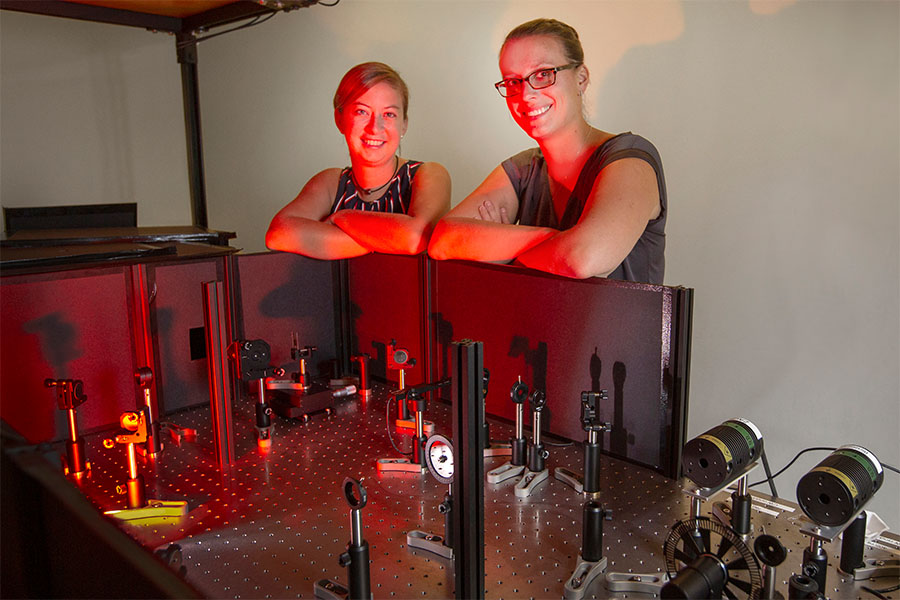

A team of Florida State University researchers is pioneering innovative ways for solar cells to absorb and use infrared light, a portion of the solar spectrum that is typically unavailable for solar cell technology.

Their work is published in two new studies in the journal Matter and the Journal of Physical Chemistry Letters.

“We’re working on a process to optimize the efficiency of solar cells,” said Lea Nienhaus, an assistant professor in the Department of Chemistry and Biochemistry. “The main drive is to optimize this process for solar applications.”

Nienhaus and postdoctoral researcher Sarah Wieghold created a new approach for solar cells to facilitate a process called photon upconversion. In photon upconversion, two low energy photons are converted into one high-energy photon that emits visible light.

Typically, the devices that help promote photon upconversion have used metal-organic molecules or semiconductor nanocrystals, but Nienhaus and Wieghold used a thin-film of lead-halide perovskites, a promising solar cell material. The perovskite is coupled with a hydrocarbon called rubrene, which emits the upconverted light.

The idea behind this process is to create more efficient solar cells that can detect and utilize infrared light. Wavelengths in the infrared spectrum do not have enough energy needed to excite the electrons in a typical solar cell and therefore aren’t a viable source of energy.

“That means there is a large amount of the solar spectrum that can’t be absorbed by a solar cell,” Nienhaus said. “We want to turn infrared light into a wavelength that could be seen and used by a solar cell.”

To improve the device efficiency, the researchers needed to create a perovskite film that was just the right thickness. They tested films that were 20, 30, 100 and 380 nanometers thick. When the thickness was above 30 nanometers, the upconversion process became efficient under solar conditions.

“To optimize the device performance, we changed the thickness of our absorber — the lead-halide perovskite film,” she said.

As Nienhaus and Wieghold were running the tests, they also discovered that the devices behaved in an unusual way.

Although the device was turning the infrared light into visible light, the perovskite was also reabsorbing some of the visible light created in the upconversion process.

“There’s a tradeoff to using the perovskite film,” Wieghold said. “More visible light created in rubrene doesn’t mean more light coming out of the device, which is counterintuitive.”

As a result, more detailed device engineering is required to optimize the ratio of infrared light in, versus visible light out of the device, researchers said.

Other co-authors of the paper published in Matter are Georgia Tech Assistant Professor Juan-Pablo Correa and FSU graduate students Alexander Bieber, Zachary VanOrman, as well as undergraduate students Lauren Daley and Meghan Leger. Bieber and VanOrman also contributed to the study published in the Journal of Physical Chemistry Letters.

Their research was supported by start-up funds from Florida State University.